Smart milk cooling solutions that save energy and money

For you as a dairy farmer milk is money, and of course it should be stored in the best way to make sure that it does not lose value.

Our goal is to provide our customers with smart milk cooling solutions that do not only take care of the milk in the best way, but also save energy and money.

At Wedholms, we construct some of the world’s best milk cooling tanks, characterized by high quality and efficiency. This ensures that the milk remains fresh and is cooled according to the dairy’s requirements regarding temperature and cooling time. Thanks to our know-how, the growth of bacteria is minimized and the milk retains all its important vitamins and minerals.

We provide comprehensive and flexible solutions focusing on heat recovery and energy saving, thus improving both sustainability and profitability.

Our research and development department is dedicated to find efficient, profitable interactions between products, systems, components and software, which result in energy-efficient solutions that bring convenience and peace of mind to our customers. In every process we strive to reuse excess water and heat in order to minimize waste.

Our most prominent innovation for energy efficiency is the “CO2 by Wedholms” milk cooling tank that was launched during 2021. The award-winning cooling system is designed to use recycled CO2 as refrigerant and transform heat from the cooling process to heat water for free. This generates significant energy savings, lowers the climate footprint and generates increased profitability for the farmer.

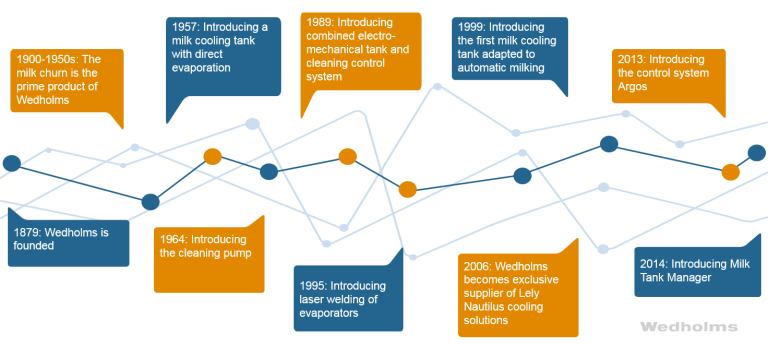

At Wedholms, we have always put great pride into staying at the cutting edge of milk cooling technology.

Today’s dairy business has high demands on modern technology as well as advanced and user-friendly solutions. With a strong focus on quality and innovation, our research and development department works in close relationship with customers all over the world with the aim to meet all their requirements, regarding maintained milk quality, reduced energy consumption and improved profitability.

One example of the significance of modern cooling technology is Argos, our system for controlling, supervising and registering all operations in the cooling and cleaning process. With Argos, farmers and technicians can get access to milk tank data via USB cable, via a local network on the farm, or through the internet. In addition, the web-based software Milk Tank Manager can provide real-time updates and operation history for better work flow, lower service costs, and better use of every milk collecting route.

Our R&D-department has developed, designed and engineered our products and systems to work in perfect symbiosis with any kind of milking system.

Our deep involvement in the entire process, from planning and configuration to long-term service and support, allows us to create tailor-made solutions regardless the size of the dairy farm. With our wide range of options, your tank can easily be adapted to the specific needs and circumstances on your farm, regardless if you have 10 or 1,000 dairy cows or more.

Our variety of market-specific options, e.g. different sizes of outlets, cooling units for different ambient temperatures and options for dairy-specific demands, makes it possible for us to offer you a tailored cooling solution, regardless where in the world your farm is located and to which dairy company you are delivering your milk.

Thanks to our ability to deliver milk cooling solutions that perfectly fit our customers’ needs, we can constantly offer uncompromising performance and security. In addition, we also have a vast network of partners for fast access to assistance and spare parts. This means that you as a customer can count on problem-free installation and operation, as well as always having service and support close at hand.

Examples of options for customization;

- Mounting of tank through wall with housing on top and rear end.

- Calibrated tank with dipstick.

- Outlet connections for DIN, SMS, DS or RJT in 2″, 2.5″ or 3″.

- Milk inlet connection for all types of automatic milking systems.Attached cooling system (if the size of the cooling system allows it).

- Tang Guard (requirement from an increasing number of dairies), integrated in the Argos control unit

- Capacity regulator for small milk quantities.10 kW heater.

- Second drain valve for separation of the cleaning water.

- Extra-long detergent hose, 10 m.

We offer a wide range of smart options to customize your cooling system to your specific needs. Learn more here. Our milk cooling tanks can also be used for a variety of other purposes, such as small-scale dairy processing facilities, slaughter houses, honey producers, etc.

Please contact your local dealer or Wedholms directly if you have any questions about our product range.

Calculate your savings!

Operating Cost and Savings Calculator – R134a vs CO₂

Quickly compare the annual operating cost and see your potential savings between a traditional R134a cooling system and a modern CO₂ solution. Efficient, eco-friendly, and cost-effective. Try the calculator now!

Wedholms ROI calculator

Enter your details

Your cost and savings

Energy consumption kWh

0 kWh

Cost per year

0 EUR

Energy consumption kWh

0 kWh

Cost per year

0 EUR

Legal disclaimer text goes here. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Would you like to learn more and get help from an advisor?

What our clients say

We are here to help!

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.